An Inventory of Eight Non-Destructive Testing Methods for Composite Materials

Composite materials are new materials that use advanced material preparation technology to optimize the combination of material components with different properties. In the 1940s, due to the needs of the aviation industry, glass fiber reinforced plastics (commonly known as fiberglass) were developed, and the name composite materials appeared. After the 1950s, high-strength and high-strength materials such as carbon fiber, graphite fiber, and boron fiber were successively developed. Modulus fiber; aramid fiber and silicon carbide fiber appeared in the 1970s. As composite materials are increasingly used in various fields, especially in aerospace, automobiles, construction, electronics, new energy and other fields, the current situation of the global composite materials industry shows a continuous growth trend.

As more and more composite materials and structures are used in various industries, knowing how to inspect them for damage is an important topic. This article will review several common non-destructive testing methods for composite materials.

Non-Destructive Testing (NDT) is a standard testing method in the composite materials industry that does not require cutting or otherwise changing the material and is the basis for manufacturing high-quality products. There are many methods to choose from for NDT, and sometimes it may be necessary to use multiple methods simultaneously to fully understand the type, size, location, and depth of defects and defects in composite laminates.

01Visual inspection

A basic and useful method of inspecting composite structures is visual inspection, which should be the first method inspectors use but is often overlooked. Viewing composite laminates under light at a shallow angle can help reveal obvious defects such as scratches, wrinkles, bridging, surface voids, peeled skin, delamination, thermal damage and other visible impact damage.

The most important advantages of visual inspection are its rapid process, as well as the relative affordability of the process and the lack of equipment, which saves money, but this method has its inherent disadvantages.

02Tap test

This is another basic check. Tap gently with a hammer or coin along the surface of the part. A bright metallic sound indicates a good structure; a dull "bang" sound indicates a defect, such as delamination or debonding.

The digital hammer measures knock response and displays in milliseconds how long it takes for the laminate to respond. The shorter the response time, the less impact the structure absorbs, indicating that the structure is solid. When a defect is found, the response time is longer, resulting in higher numbers on the display.

This method is more effective in thin laminates less than 3.05 mm thick and has no effect on very thick laminates. Another disadvantage is that it can sometimes give false readings, such as when another structure is attached to the back.

03Ultrasonic testing

This is currently the most widely used non-destructive testing method. Ultrasonic testing (UT) works by sending high-frequency (0.5~25 MHz) energy waves into laminates, capturing and quantifying the amplitude and flight time of these waveforms to analyze and understand material properties and structural changes. There are two main methods used:

Pulse-echo ultrasonic testing: Single-sided ultrasonic testing can be accomplished with pulse-echo technology. This method works with a single search unit as a transmitting and receiving transducer, excited by high-voltage pulses. Each electrical pulse activates the transducer element. This element converts electrical energy into mechanical energy in the form of ultrasonic waves. Sonic energy enters the test section through a Teflon® or methacrylate contact tip. A waveform is generated in the test section and picked up by the transducer element. Any change in the amplitude of the received signal, or the time it takes for the echo to return to the transducer, indicates a defect. Pulse echo inspection is used to detect delamination, cracks, pores, water and debonding of bonded parts, but it is more difficult to detect debonding or defects between the sandwich skin and honeycomb core.

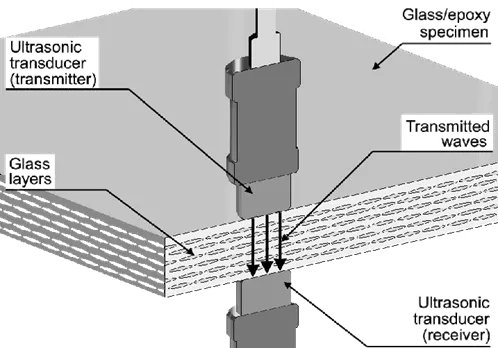

Transmission Ultrasound Inspection: Uses two transducers, one on each side of the area being inspected. Ultrasonic signals are transmitted from one transducer to other sensors. An instrument is then used to measure the loss of signal strength. The instrument expresses loss as a percentage of the original signal strength, or in decibels. Compare signal loss to reference standards. Areas with losses greater than the reference standard are represented as defective areas.

Low- and high-frequency bond testers: This bond tester uses an inspection probe with one or two transducers. High-frequency bond testers are used to detect delaminations and voids and can detect defects as small as 0.5 inches in diameter, but cannot detect surface-to-honeycomb core debonding or voids; low-frequency bond testers use two sensors with Good at detecting delaminations, voids, and peeling of the honeycomb core, but cannot detect which side of the part is damaged and cannot detect defects smaller than 1.0 inches.

Phased array ultrasonic testing: Phased array testing is one of the latest ultrasonic testing methods for structural defects in composite materials. It operates on the same principle as the pulse-echo method, but it uses dozens or even more sensors simultaneously, greatly speeding up the detection process.

04Thermal imaging detection

The working principle of pulsed infrared thermal imaging is to use active heating technology to automatically record the surface defects of the test piece and the temperature difference caused by the different thermal properties of the base material through the infrared thermal imaging system, and then determine the damage on the surface and inside of the measured object.

This method is non-contact, real-time, efficient, and intuitive, and is very suitable for detecting debonding, porosity, peeling, delamination, and delamination-type area-type defects in composite sheets and metal bonding structures, especially when The infrared thermal wave detection method can be used when parts or components cannot be immersed in water for ultrasonic C-scan inspection, and the surface shape of the part makes ultrasonic inspection difficult.

05Ray detection

Radiographic testing (RT), commonly referred to as X-ray inspection, is a very useful NDT method because it essentially allows rays to penetrate inside the part to form a visual view. This testing method involves passing X-rays through the component or assembly being tested while recording the absorption of the rays on a film sensitive to X-rays. After the exposed film is developed, inspectors analyze and record the changes in exposure opacity on the film, effectively creating a visual image of the detailed relationships within the component.

Since this method records changes in total density through thickness, it is not the preferred method for detecting defects such as delamination in a plane perpendicular to the direction of the ray. But it is the most effective method for detecting defects parallel to the centerline of the X-ray beam. Internal anomalies such as delamination in the corners, crushed cores, broken cores, water in the core cells, voids in the foam adhesive joints, and the relative position of internal details can all be easily detected by X Rays see.

Most composite materials are nearly transparent to X-rays, so low-energy rays must be used. Due to safety concerns, use around aircraft is impractical. Operators should always use adequate lead shielding protection, because either the X-ray tube or its scattered radiation may expose them to direct radiation, and it is necessary to maintain a minimum safe distance from the radiation source.

There are many types of radiographic inspection technology, each with specific applications. Conventional radiography is most useful when the part is neither too thick nor too thin; for thin parts 1 to 5 mm, low-voltage radiography is used; and gamma radiography is suitable for thick parts.

Neutron radiography is a complementary technique to X-ray radiography, both of which image the internal features of a sample through visual attenuation of the medium. The transmission of neutrons through a medium depends on the neutron cross-section of the nuclei in the medium, and the differential attenuation of neutrons through the medium can be measured, plotted, and then visualized. The main advantage of neutron radiography is its ability to reveal light elements such as hydrogen found in corrosion and water.

06 Shear imaging test

Shear imaging testing is a laser optical method that detects and measures out-of-plane deformation of parts by using an image shear interferometer.

Parts are first measured under no load conditions and then again under applied loads for thermal, mechanical vibration, acoustic vibration, pressure, vacuum, electric fields, magnetic fields, microwave or mechanical, etc. This allows the camera to see defects so that they can be Capture of iso-strain fringe patterns on the surface of laminates with subsurface defects. Computer software extrapolates the wrapped phase map image and creates an unfolded phase map that is converted into an integrated visible image for display and evaluation.

It is important to note that this technology can quickly show the location of the defect, but further inspection using ultrasonic technology is required to determine the depth.

07Acoustic emission detection

Acoustic Emission (AE) testing is a testing technology that evaluates the overall quality level of composite components by detecting and analyzing the acoustic emission signals generated by composite materials or structures during the loading process. It is an effective testing technology. defect analysis method.

This method can reflect the development of damage and failure mode in composite materials, predict the final load-bearing strength of components, and determine the weak areas of component quality.

Acoustic emission technology is a very practical technical means for testing the overall quality level of composite structures. It is simple and convenient to use. It can not only test the mechanical properties of materials, but also obtain valuable information on the dynamic deformation and damage process of materials. There are three main methods used:

Parameter analysis method: By recording and analyzing the characteristic parameters of the acoustic emission signal, such as amplitude, energy, duration, ringing count, and number of events, the damage and destruction characteristics of the material, such as the degree and location of damage, damage mechanism, etc., are analyzed. Its biggest disadvantage is that information about the nature of the AE source is often obscured or blurred by the characteristics of the resonant sensor itself, and the repeatability of its experimental results is very poor.

Waveform analysis method: record and analyze the waveform of the acoustic emission signal to obtain the spectrum and related functions of the signal. By analyzing the frequency characteristics of damage caused by different stages and different mechanisms of the material, the damage characteristics of the material can be obtained.

Spectrum analysis method: It can be divided into classic spectrum analysis and modern spectrum analysis. It is the most commonly used analysis method in acoustic emission signal processing. Both spectral analysis methods convert the acoustic emission signal from the time domain to the frequency domain, study various characteristics of the acoustic emission signal in the frequency domain, and find and identify the intrinsic information of the acoustic emission source. However, spectrum analysis of signals requires that the signal being analyzed is a periodic and stationary signal, and spectrum analysis is a global analysis method that ignores changes in local information.

08 Sound-Ultrasonic Testing

Acoustic-Ultrasonic (AU) testing is a combined method of acoustic and ultrasonic testing. It is mainly used to detect and study the group of fine defects distributed in materials and their overall impact on the mechanical properties of the structure (strength or stiffness, etc.). It belongs to Material integrity assessment techniques.

In non-destructive testing, sonic/ultrasonic type testing has great potential based on optimal economy, flexibility and sensitivity. This is a useful method because it allows non-critical defects to be viewed and evaluated. A second advantage is that it is a good indicator of accumulated damage in a structure due to fatigue loading or impact damage.

Acoustic-ultrasonic amplitude C scanning technology can also effectively detect the bonding interface between composite materials and metal materials, and overcomes the shortcomings of low signal clarity of ultrasonic reflection technology and poor sensor accessibility of ultrasonic transmission technology.